Electronic grade glass fiber cloth for the electronics industry

The process usually uses quartz sand, limestone, pyrophyllite and other minerals as raw materials, with soda ash, boric acid and other chemical raw materials fused into glass, and then pulled into fibrous materials in the molten state. Hundreds or even thousands of monofilaments can form a bundle of fiberglass fibers, which can be twisted and threaded to make fiberglass yarn, which can be further woven into fiberglass cloth. Electronic cloth, as the basic material of copper-clad plate, is widely used in smart phones, consumer electronics, servers, automotive electronics, national defense, aerospace and other high-tech electronic products. In recent years, the global sales scale of electronic cloth has shown steady growth.

According to the different thickness of electronic cloth, it can be divided into four types: thick electronic cloth, thin electronic cloth, ultra-thin electronic cloth and extremely thin electronic cloth. Electronic cloth of different thickness belongs to different grades, among which, thick cloth belongs to low-end electronic cloth, thin cloth belongs to mid-end electronic cloth, and ultra-thin cloth and ultra-thin cloth belong to high-end electronic cloth. According to the national classification standard, there are 15 kinds of electronic cloth in common use, among which the thickness of the thinnest electronic cloth is 12μm, and the thickness of the thickest electronic cloth is 254μm. At present, ultra-thin and ultra-thin electronic cloth is mainly used in high-end smart phones, IC carrier board and other fields. Due to high technical requirements, only a few manufacturers such as Japan NTB(Nitto Textile) in the world have the corresponding production capacity, and domestic Chongqing International and Guangyuan Xincai can also realize the production of 106 ultra-thin cloth. The middle end electronic cloth is mainly used for general smart phones, servers and automotive electronic materials, China Boulder, Taishan glass fiber, Chongqing International can realize the production of different specifications of thin cloth or its corresponding yarn; 7628 thick cloth is mainly used for desktop computer, printer, LCD TV, audio and other low-end electronic products PCB.

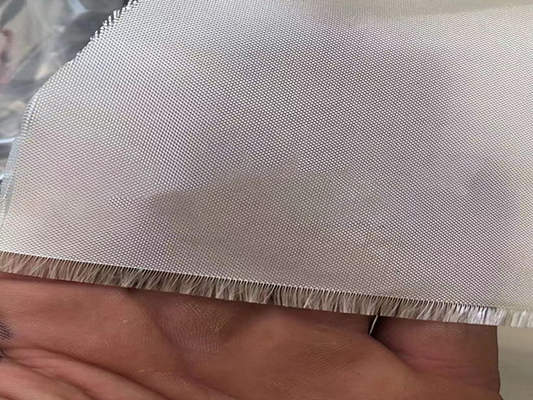

The direct upstream related industry of the electronic fabric industry is electronic yarn. The textile process of electronic yarn is similar to that of cotton. After the enterprise produces or purchases electronic yarn, the weft yarn and warp yarn are interleaved by jet loom to form the fabric with staggered up and down, and each other's ups and downs are required to be plain structure. In recent years, the domestic production capacity of electronic yarn has been increasing. At present, China's electronic yarn production capacity has reached more than 70% of the global production capacity. By the end of 2020, the total production capacity of China's electronic yarn is 804,000 tons, and the production capacity is about 746,000 tons.

Because the chemical composition and physical structure of electronic yarn determine the dielectric properties, heat resistance, drilling processing and surface smoothness of the copper clad plate, the binding degree between manufacturers and customers is high, the brand barrier is obvious. In addition, the investment intensity of fixed assets of electronic yarn is very great. The average initial production line investment of the industry is about 350 million yuan/ton. Because of the high market threshold of the electronic yarn industry, the domestic production capacity is relatively concentrated, among which South Asia must Cheng, Kingboard Chemical is the two largest domestic electronic yarn production enterprises, the industry CR3 reached 49.3%. In the field of medium and low-end electronic cloth, due to the low technical threshold, relatively more manufacturers and fierce competition, high-end electronic cloth manufacturing requires special technology and special materials, so the competition between manufacturers is less. At present, the major electronic glass fiber manufacturers in China have begun to base on the advantages of production capacity and electronic fabric experience, and constantly innovate technology, seeking to supply high-end electronic yarn independently.

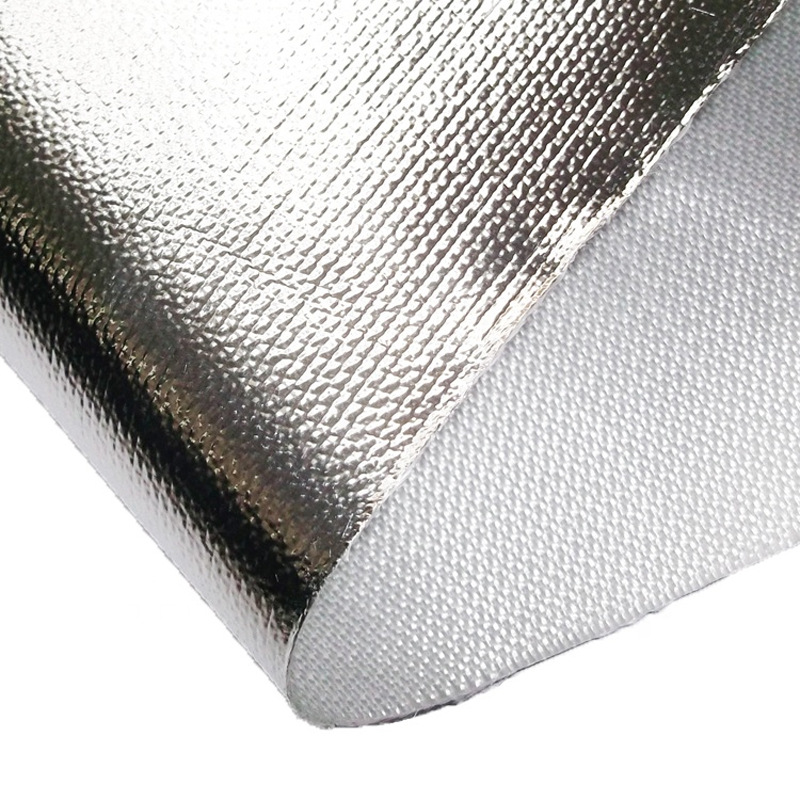

Copper coated plate is a kind of plate-like material made of electronic glass fiber cloth as reinforcement material, impregnated with resin and covered with copper foil on one or both sides by hot pressing. It bears the three functions of conducting, insulating and supporting the printed circuit board, and is the core material for making printed circuit board. Our country is the first big country in the world of copper cladding plate production. The market size of electronic cloth is closely related to the direct downstream market of copper cladding plate, and the demand of copper cladding plate is closely related to the downstream market of printed circuit boards. In 2019, the annual sales volume of copper clad plate industry exceeded 700 million square meters. In 2020, domestic manufacturers such as Shengyi Technology, Jin 'an Guoji, Nanya New Material and Huacheng New Material are also building new production lines with annual output of one million and ten million square meters of copper clad plate. In the future, with the development of the downstream printed circuit board and electronic information industry, the copper clad industry will continue to grow, which will bring great new market demand to the electronic cloth industry.

In recent years, the proportion of communication increased gradually (33%), while that of computer decreased (28.6%). Consumer electronics and automotive electronics increased steadily. With the explosive growth of smart phones and wearable devices promoted by consumption upgrade, intelligent consumer electronics are gradually developing towards miniaturization, thinness, intelligence and portability, which makes printed circuit boards, as the carrier of circuits, need to meet the demand for high-density interconnection. In the future, the varieties of high-end ultra-thin and ultra-thin electronic cloth will continue to increase. The depth and breadth of application fields will continue to expand.