PVC coated glass fiber cloth

PVC adds a special function to the fabric, so it is also called functional coating fabric. pvc, referred to as pvc, is a thermoplastic resin polymerized by vinyl chloride under the action of initiator. It is a homopolymer of vinyl chloride. PVC is a white powder with amorphous structure and small branching degree. pvc has the characteristics of flame retardant, solvent resistance, heat resistance, good comprehensive mechanical properties, etc., widely used in packaging materials, artificial leather, plastic products and other soft products as well as pipe, profile, plate and other hard products, but pvc light and heat stability is poor, above 100℃ or after a long time of sunlight exposure, it will decompose and produce hydrogen chloride, and further automatic catalytic decomposition, It causes discoloration and decreases the physical and mechanical properties rapidly. In practical application, stabilizers must be added to improve the stability of temperature and light. In order to increase the folding resistance, wear resistance and cold resistance of the existing PVC coated cloth, thermoplastic polyurethane, namely tpu, is added. tpu has both the plastic processing performance and the physical and mechanical characteristics of rubber. tpu has high strength, high modulus, high elongation and high elasticity, excellent wear resistance, oil resistance, low temperature resistance, aging resistance and other characteristics. It is very common to use pvc as a mixed coating.

PVC coated cloth is to add coating agent on the basis of white embryo, PVC coated cloth process is in the production process of artificial leather, plastic particles should first be heated and stirred into paste, evenly coated in T/C knitted fabric base according to the specified thickness, and then into the foaming furnace for foaming, so that it can adapt to the production of different products, different needs of the degree of hardness.

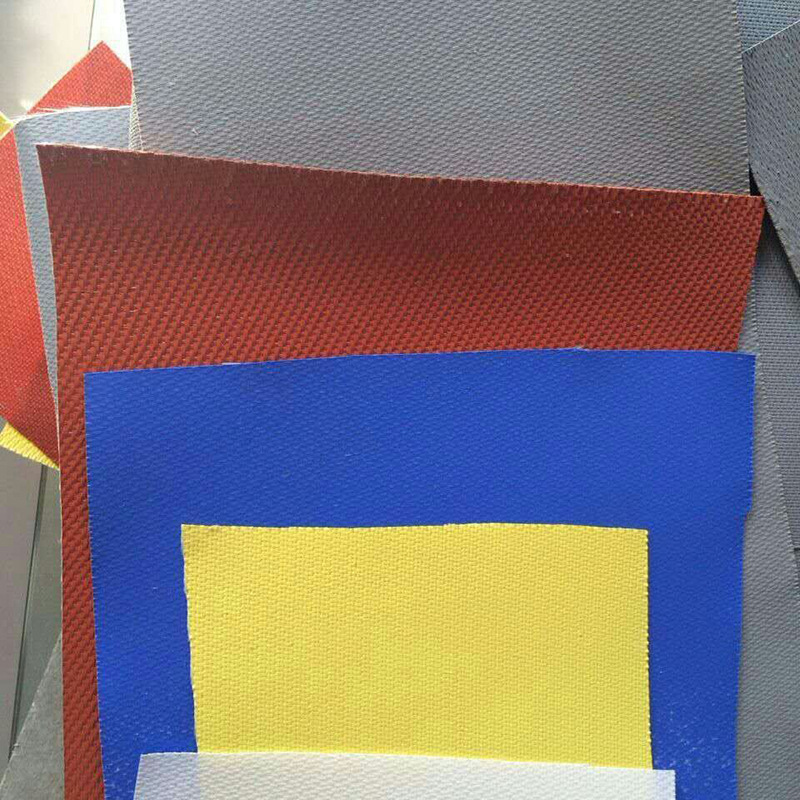

PVC coated cloth with glass fiber cloth, cotton cloth, chemical fiber cloth as the base cloth, coated with special technology, the main performance characteristics: waterproof and flame retardant, anti-mold and cold, anti-corrosion, anti-aging, anti-ultraviolet, good heat and insulation performance, easy to clean and so on.

Waterproof agent can also be added to PVC coating. After PVC coating can be waterproof, it is more widely used.

The use of waterproof Oxford cloth is different, waterproof function also has advantages and disadvantages. Good quality waterproof Oxford cloth can be like a bucket of water, will not leak, rain, water will slide down, the surface of the water only need to gently wipe the surface of the water traces, will not penetrate into the interior. And the requirements are not high waterproof Oxford cloth is: encounter rain, part of the rain will penetrate, but there will be no water drops, but the life is not long.

1. Peng cloth class: widely used in train. automobile transportation with Peng cloth. food storage. wharf. warehouse cover cloth. (mainly waterproof)

2. Air duct cloth: drilling tower clothing. all kinds of tents. mine air duct. etc.

(mainly waterproof. fire. cold. corrosion. etc.)

3. heat preservation: used to wrap all kinds of pipes and equipment. can be cut into strips.

4. Make it into fireproof tape.

5. fireproof welding blanket (welding protection for ships and other). fire isolation barrier. fire tent.

6. for building membrane material. the production of various landscape engineering.

7. set up all kinds of tents. temporary rooms. etc.