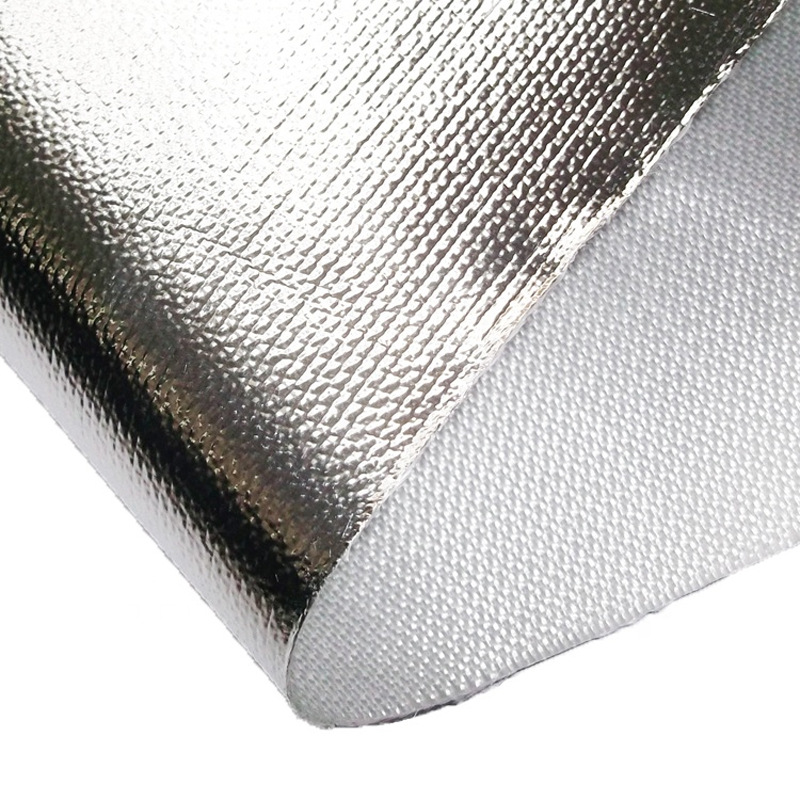

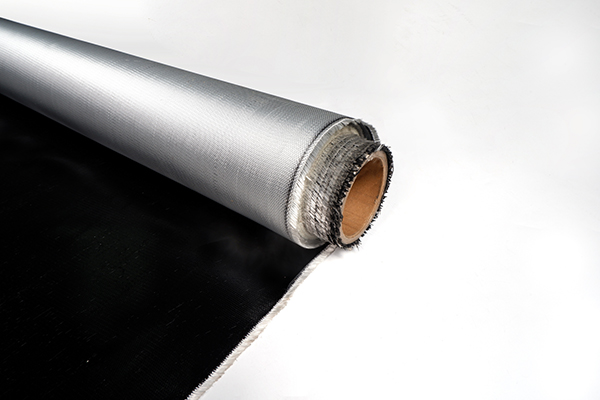

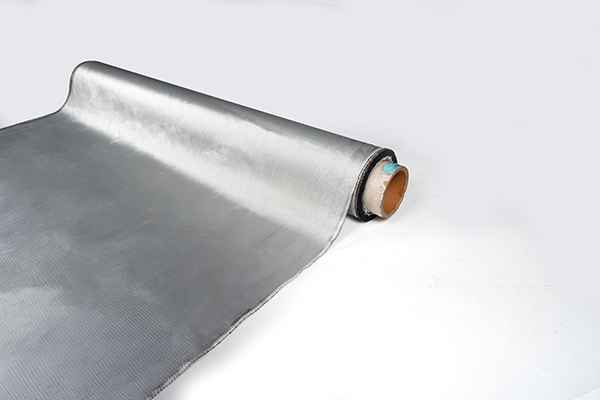

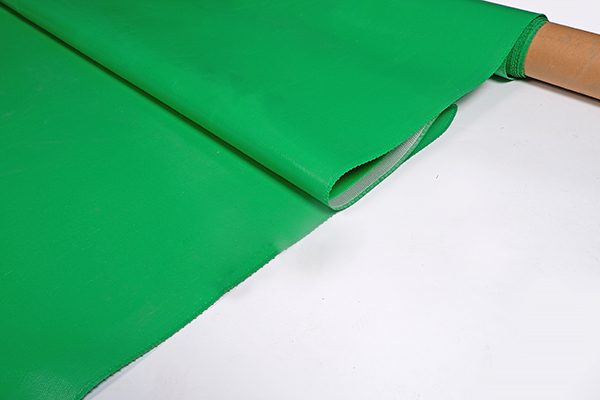

Glass fiber heat insulation fire insulation flame retardant non-alkali cloth

Glass fiber (formerly known as: glass fiber) is a kind of inorganic nonmetallic material with excellent performance. It has a wide variety of advantages, such as good insulation, strong heat resistance, good corrosion resistance and high mechanical strength, but its disadvantages are brittleness and poor wear resistance. Glass fiber is usually used as reinforcement materials in composite materials, electrical insulation materials and thermal insulation materials, electric roadbed board and other fields of the national economy.

1. Used for low temperature -196℃. high temperature 300℃ between. with weather resistance.

2. Bon-adhesive. not easy to adhere to any substance.

3. Chemical corrosion resistance. strong acid. alkali. aqua regia and a variety of organic solvent corrosion.

4. Low friction coefficient. is the best choice of oil-free self-lubrication.

5. Light transmittance of 6 ~ 13 %.

6. With high insulation performance. anti-UV. anti-static.

7. High intensity. It has good mechanical properties.

8. Drug resistance.

Glass fiber cloth is used for hand paste into the process, glass fiber reinforced material grid cloth is mainly in the hull, storage tank, cooling tower, ship, vehicle, tank, building structure material. Glass fiber cloth in industry is mainly used for: heat insulation, fire prevention, flame retardant. The material absorbs a lot of heat when it is burned by a flame and can prevent the flame from passing through, trapping air.

1. According to the composition: mainly alkali, alkali, high alkali (is to classify the composition of alkali metal oxide in glass fiber), of course, there are also classification by other components, but too many varieties, not a list.

2. According to the manufacturing process: crucible drawing and pool kiln drawing.

3. According to the variety: there are split yarn, direct yarn, jet yarn, etc.

In addition, it is according to the single fiber diameter, TEX number, twist, infiltrating agent type to distinguish.

The classification of glass fiber cloth and fiber yarn is similar, in addition to the above, also includes: weaving, gram weight, amplitude, etc.

Glass fiber cloth and glass material difference

Glass fiber cloth and glass main material difference is not big, mainly due to the production of material requirements are different, so there are some differences in the formula. The silica content of plate glass is about 70-75%, and the silica content of glass fiber is generally below 60%.

Glass is inorganic material after high temperature melting (above 800 degrees, domestic glass is generally melted at 1100 degrees). , below the softening point temperature, no chemical changes will occur. Above the temperature of the softening point, it only softens, melts or decomposes, without combustion.

Glass fiber cloth is the glass pulled into very fine glass wire, at this time the glass wire has a very good softness. The glass filament is spun into yarn and then passed through a loom to make fiberglass cloth. Because the glass filament is very fine, the surface area per unit mass is very large, so the temperature resistance is reduced. Just like a candle can melt fine copper wire.

But glass doesn't burn. The combustion that we can see is actually to improve the performance of the fiberglass cloth, and the surface of the fiberglass cloth coated with resin material, or attached impurities. Pure glass fiber cloth or coated with some high temperature resistant coating, it can be made of refractory clothing, refractory gloves, refractory blanket products. However, if it comes into contact with the skin directly, the broken fibers will irritate the skin more and cause itching.

General conventional glass fiber monofilm diameter in more than 9-13 microns, below 6 microns of glass fiber float, can directly into the lung tube, can cause respiratory disease, so pay special attention to, 6 microns below generally are imported. Professional masks must be worn during production operations. If you are exposed to it often, it can get sucked into your lungs and cause pneumoconiosis.

If the body touches the glass fiber, the skin is not good will be allergic will itch, but generally will not have great harm, the skin is not good may be a small bag, that is allergic phenomenon.

If it is difficult to remove it from clothes, beat it several times in a windy place. After washing and drying, it is easier to remove it by beating it with a branch.