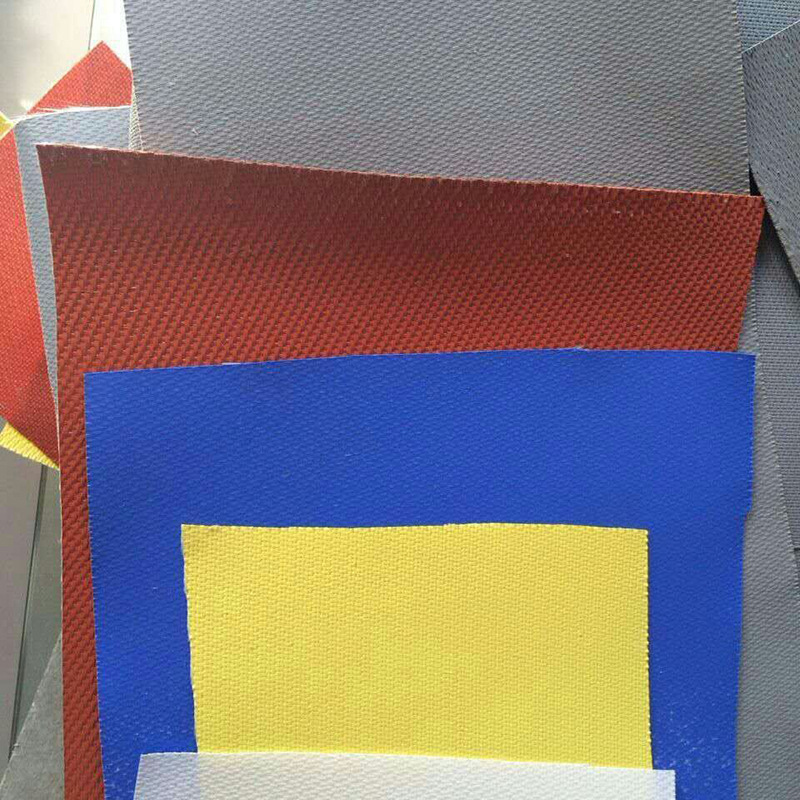

Glass fiber fire blanket, high silicon oxygen fire blanket, carbon fiber fire blanket, ceramic fiber fire blanket

Fire blanket or called fire quilt, fire quilt, fire blanket, fire blanket, flame retardant blanket, escape blanket.

According to the base material classification: because of the different base cloth, the product name is as follows cotton fire blanket, asbestos fire blanket, glass fiber fire blanket, high silicon oxygen fire blanket, carbon fiber fire blanket, ceramic fiber fire blanket and so on.

Classification by use: domestic fire blanket, industrial fire blanket.

It is an ideal and effective outer protective layer for people and things that must be kept away from the heat source body, and it is very easy to wrap the uneven surface of the object, enterprises, shops, ships, cars, civil buildings on a simple fire extinguishing tool, especially suitable for home kitchens, hotels, entertainment places, gas stations and other easy to catch fire occasions, to prevent the spread of fire.

It is the most ideal and effective outer protective layer for people and objects that need to be kept away from heat sources, and it is very easy to cover objects with uneven surfaces.

In the case of no damage can be reused, compared with water base type, dry powder type fire extinguishing appliances:

1. No expiration period;

2. It will not produce secondary pollution after use;

3. Insulation and high temperature resistance;

4. Easy to carry, simple configuration, can be used quickly, no damage can be reused.

Since the blanket is a very soft fire-fighting instrument, it can be used to extinguish the fire at the fastest speed in the initial stage of the fire.

To control the spread of the disaster, it can also be used as a protective item for timely escape. As long as the blanket is wrapped in the whole body, because the blanket itself has fire prevention.

Heat insulation characteristics, in the escape process, the human body can be well protected.

Non-combustible, high temperature resistance (550~1100℃), soft texture, smooth, tight, and does not stimulate the skin, need to stay away from the heat source body, is an ideal and effective outer protective layer, and very easy to bandage the surface of uneven objects, in the case of no damage can be reused.

Cover fire source and block air to achieve the purpose of fire extinguishing.age can be reused.

1. In the event of a fire, the fire escape blanket on their own body or wrap the body of the rescued object, quickly escape from the fire, for self-rescue or safe evacuation of people to provide a good help. If there is a fire accident, you can put on a fire blanket, it can greatly reduce the risk of being burned.

2. Enterprises, shopping malls, ships, cars, civil buildings and other occasions of a simple initial fire extinguishing tool.

Fire blanket is made of fiber - like refractory material. Refractory fiber has the characteristics of general fiber, such as soft, elastic, a certain tensile strength, it can be further processed into a variety of paper, line, rope, belt, blanket and felt products; It also has high temperature resistance and corrosion resistance that the general fiber does not have. As a refractory heat insulation material, has been widely used in metallurgy, chemical industry, machinery, building materials, shipbuilding, aviation, aerospace and other industrial sectors.

Refractory fiber is divided into amorphous (glassy) and polycrystalline (crystallized) two categories. Amorphous refractory fibers, including aluminum silicate, high purity aluminum silicate, chromium containing aluminum silicate and high aluminum refractory fibers. Polycrystalline refractory fibers, including mullite, alumina and zirconia. (Table 1) There are also classified according to the maximum allowable service temperature of refractory fiber.

Refractory fiber is a good infrared radiation material, with good thermal capacity and infrared heating effect, the use of refractory fiber products can effectively save energy, is the ideal energy saving and efficiency materials. Production practice has proved that the application of refractory fiber in continuous heating industrial furnace can save more than 15% energy, used in intermittent industrial heating furnace can save more than 30% energy, at the same time can improve productivity and improve product quality, achieve light and large scale furnace structure, comprehensive performance is good. Refractory fiber soft, good elasticity, or the ideal sealing material, because of insulation, noise reduction, oxidation resistance, oil resistance and water resistance, convenient construction, so in metallurgy, building materials, petroleum, chemical industry, shipbuilding, electric power, aerospace and other fields widely used.

Polycrystalline refractory fiber is a new high temperature insulation material developed after amorphous refractory fiber in the early 1970s. It is mainly used in high temperature kiln where the working temperature is higher than 1400℃. It can save energy by 25% ~ 40%. Polycrystalline refractory fiber can also be used as composite reinforcement material and catalyst support, and the application effect is good. Polycrystalline refractory fiber can also be used in the field of aerospace missiles and atomic energy. At present, the main polycrystalline refractory fibers produced and applied in the world are polycrystalline alumina fibers (Al2O380% ~ 90%, SiO221% ~ 20%), polycrystalline mullite fibers (Al2O372% ~ 79%, SiO221% ~ 28%) and polycrystalline zirconia fibers (ZrO292%, Y2O38%).