Glass fiber checkered fabric is non twist roving plain fabric, is an important base material of hand paste glass fiber reinforced plastic. The strength of the gingham cloth is mainly in the warp and weft direction of the fabric. For the occasions requiring high warp or weft strength, it can also be woven into one-way cloth, which can be arranged in the warp or weft direction more untwisted roving, single warp cloth, single weft cloth.

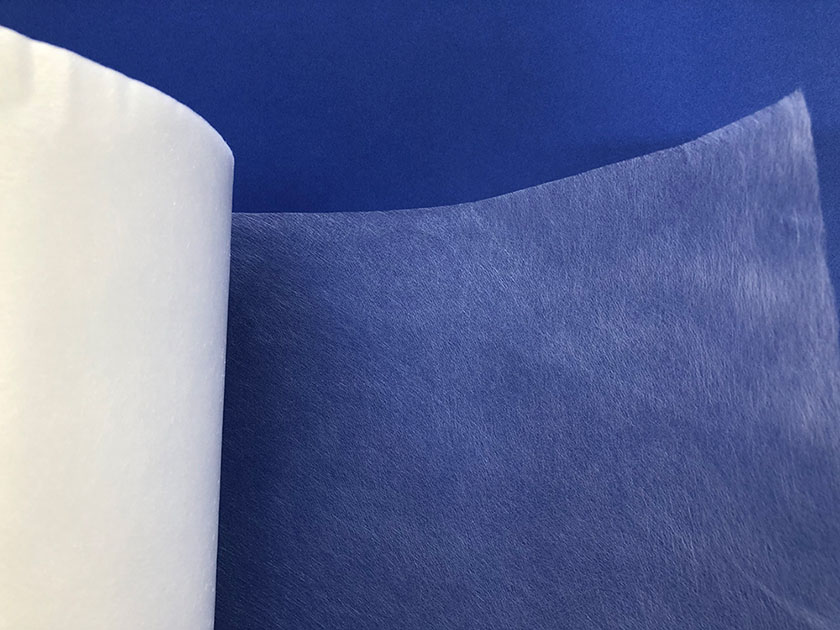

Glass fiber cloth is the glass pulled into very fine glass wire, at this time the glass wire has a very good softness. The glass filament is spun into yarn and then passed through a loom to make fiberglass cloth. Because the glass filament is extremely fine, the surface area per unit mass is large, so the temperature resistance is reduced. Just like a candle can melt fine copper wire. But glass doesn't burn. The combustion that we can see is actually the resin material coated on the surface of the glass fiber cloth, or attached impurities, in order to improve the performance of the glass fiber cloth. Pure glass fiber cloth or coated with some high temperature resistant coating, it can be made of refractory clothing, refractory gloves, refractory blanket products. However, if it comes into contact with the skin directly, the broken fibers will irritate the skin more and cause itching.

Glass fiber cloth is used for hand paste into the process, glass fiber reinforced material grid cloth is mainly in the hull, storage tank, cooling tower, ship, vehicle, tank, building structure material. Glass fiber cloth in industry is mainly used for: heat insulation, fire prevention, flame retardant. The material absorbs a lot of heat when it is burned by a flame and can prevent the flame from passing through, trapping air.

1. According to the composition: mainly alkali, alkali, high alkali (is to classify the composition of alkali metal oxide in glass fiber), of course, there are also classification by other components, but too many varieties, not a list.

2. According to the manufacturing process: crucible drawing and pool kiln drawing.

3. According to the variety: there are split yarn, direct yarn, jet yarn, etc.

In addition, it is according to the single fiber diameter, TEX number, twist, infiltrating agent type to distinguish. The classification of glass fiber cloth and fiber yarn is similar, in addition to the above, also includes: weaving, gram weight, amplitude, etc.

Glass fiber cloth and glass main material difference: glass fiber cloth and glass main material difference is not big, mainly due to the production of material requirements are different, so there are some differences in the formula. The silica content of plate glass is about 70-75%, and the silica content of glass fiber is generally below 60%.

Post time: Mar-08-2023