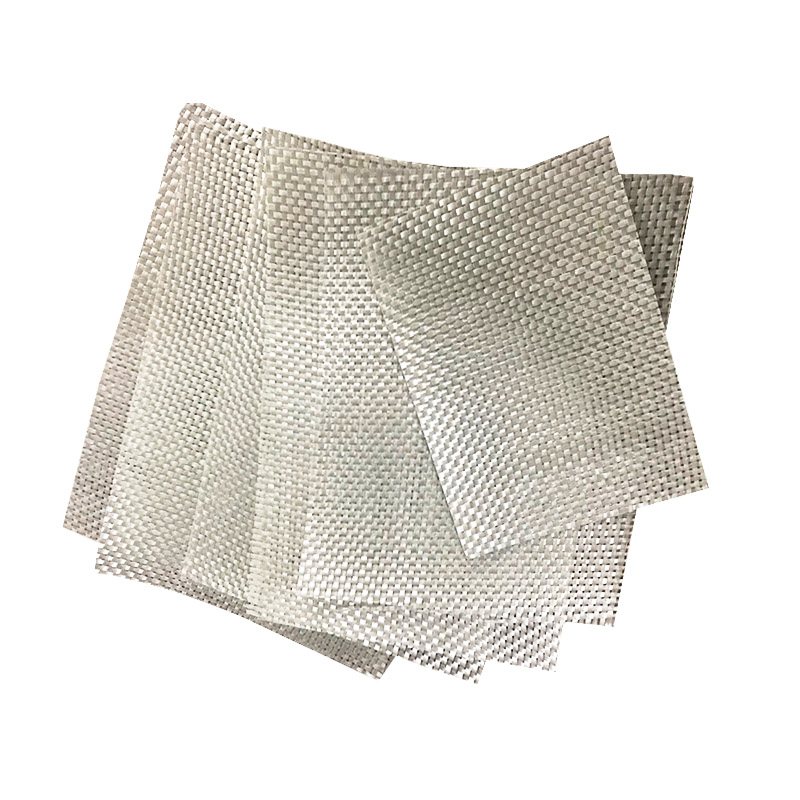

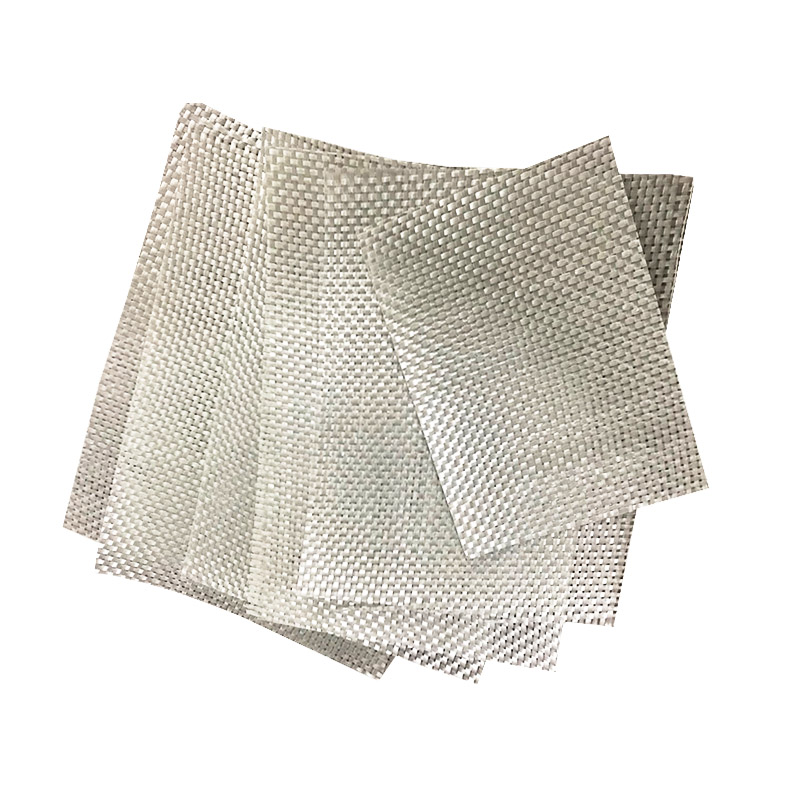

Corrosion resistant glass fiber steel base cloth

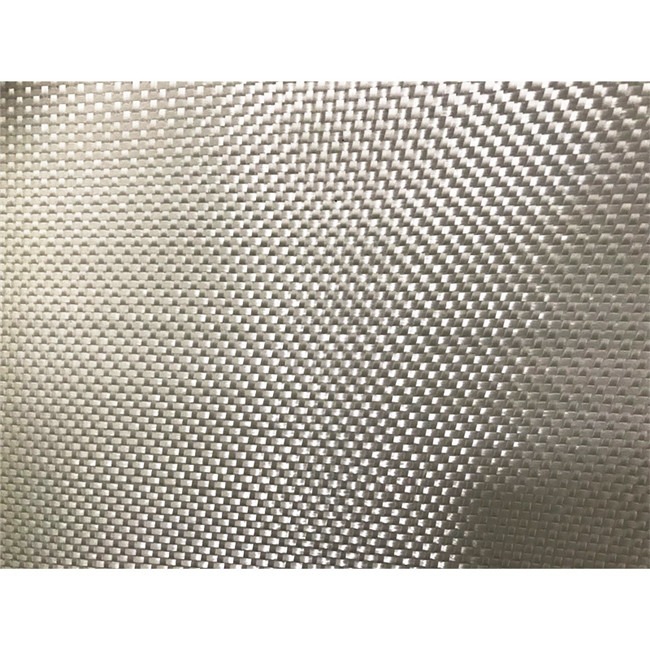

Glass fiber reinforced plastic fabric is made of medium alkali or non alkali non twist roving, non twist roving is treated by silane coupling agent, easy to be infiltrated by resin, corrosion resistance, high strength, and good interlayer adhesion, is a glass fiber fiber fabric for glass fiber reinforced plastic anticorrosion, can apply to a variety of curved surface engineering construction.

Fiberglass base cloth (excluding coarse gauze and cut felt) is one of the specific glass fiber products manufactured in a country at present. Taking a factory in China as an example, the annual output of FRP products with FRP base cloth as raw material has reached more than 1000 tons. With the development trend of glass fiber reinforced plastic industry, the type and quality of glass fiber reinforced plastic base cloth are specified. The quality of glass fiber reinforced plastic fabric includes glass composition, the appropriate number of raw silk, the type of infiltrating agent, the number of yarn strands, yarn twist, fabric organization and good shape quality of fabric and so on. Now the performance of glass fiber reinforced plastic/production cost has a great impact on the shape quality, fabric structure and resin compatibility and other factors to talk about some views. The overview of the application of FRP base cloth in the world is that at present, the glass fiber products as raw materials for FRP improvement abroad are mainly non-twist roving, cut raw yarn, and a variety of felt, plaid cloth and non-woven raw materials. For example, non-textile materials in the United States have accounted for about 65% of the total output value of continuous fibers. In Japan, most of the non-woven raw materials, accounting for 90% of the total output value in 1975. FRP base cloth is only used for some of the higher strength of the electrical insulation sheet, tube, laminate and other FRP production. With the development trend of fiberglass industry in China, the proportion of glass fiber used to manufacture fiberglass has gradually increased. In 1983, it accounted for about 40% of the total output value of glass fiber in China. According to the investigation, there are more than 30 types of glass fiber products in China, and nearly 200 specifications, models and brands (including the unified enterprise standard) (40 official ministry standards). There are about 7~8 kinds of FRP base cloth among them. There is no standard or trial production stage for cutting raw silk and various enhanced felt tablets.

Glass fiber reinforced plastic fabric is made of medium alkali or non alkali non twist roving, non twist roving is treated by silane coupling agent, easy to be infiltrated by resin, corrosion resistance, high strength, and good interlayer adhesion, is a glass fiber fiber fabric for glass fiber reinforced plastic anticorrosion, can apply to a variety of curved surface engineering construction.

Fiberglass base cloth (excluding coarse gauze and cut felt) is one of the specific glass fiber products manufactured in a country at present. Taking a factory in China as an example, the annual output of FRP products with FRP base cloth as raw material has reached more than 1000 tons. With the development trend of glass fiber reinforced plastic industry, the type and quality of glass fiber reinforced plastic base cloth are specified. The quality of glass fiber reinforced plastic fabric includes glass composition, the appropriate number of raw silk, the type of infiltrating agent, the number of yarn strands, yarn twist, fabric organization and good shape quality of fabric and so on. Now the performance of glass fiber reinforced plastic/production cost has a great impact on the shape quality, fabric structure and resin compatibility and other factors to talk about some views. The overview of the application of FRP base cloth in the world is that at present, the glass fiber products as raw materials for FRP improvement abroad are mainly non-twist roving, cut raw yarn, and a variety of felt, plaid cloth and non-woven raw materials. For example, non-textile materials in the United States have accounted for about 65% of the total output value of continuous fibers. In Japan, most of the non-woven raw materials, accounting for 90% of the total output value in 1975. FRP base cloth is only used for some of the higher strength of the electrical insulation sheet, tube, laminate and other FRP production. With the development trend of fiberglass industry in China, the proportion of glass fiber used to manufacture fiberglass has gradually increased. In 1983, it accounted for about 40% of the total output value of glass fiber in China. According to the investigation, there are more than 30 types of glass fiber products in China, and nearly 200 specifications, models and brands (including the unified enterprise standard) (40 official ministry standards). There are about 7~8 kinds of FRP base cloth among them. There is no standard or trial production stage for cutting raw silk and various enhanced felt tablets.